3+N产品应用

馆长:吴权派 eris@meanwell.com

+886-2-2299-6100 #350

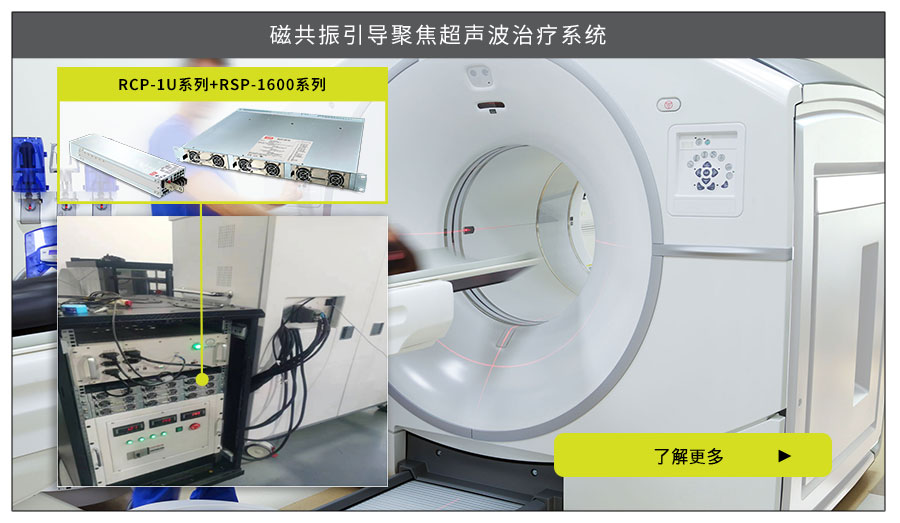

明纬拥有超过一万种标准电源机型与全球专业技术服务团队,透过相关技术咨询服务,可依客户需求提供产品与组合式系统解决方案。 3+N产品涵盖模组电源、机架式电源、机柜系统电源等产品,结合数位智能控制器或搭配超过一万种标准电源机型组合应用,提供多产业应用。 产品策略以软体(software)、系统(system)、解决方案(solution)、和服务(service)为框架,提供客户高性价比、高产值效益、高附加价值的系统解决方案。

最新产品

SHP-30K系列

30KW 三相三线式超高瓦数工业级标准电源

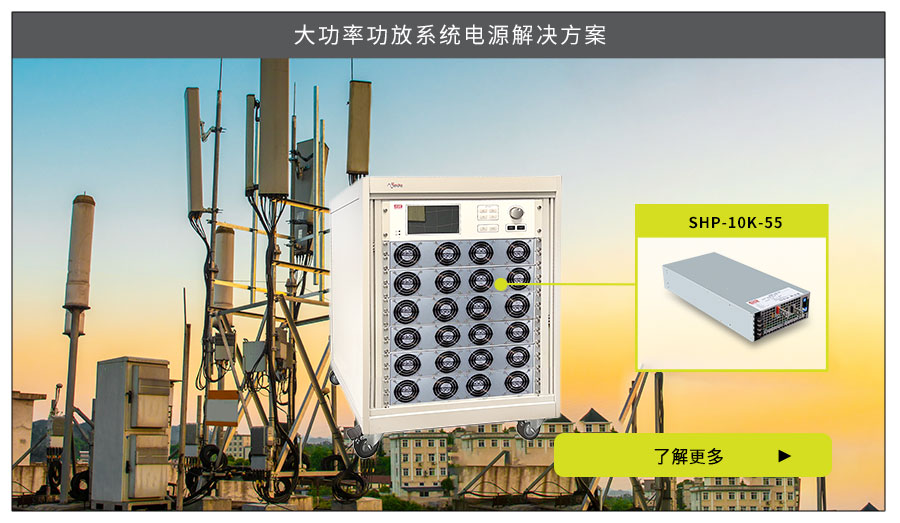

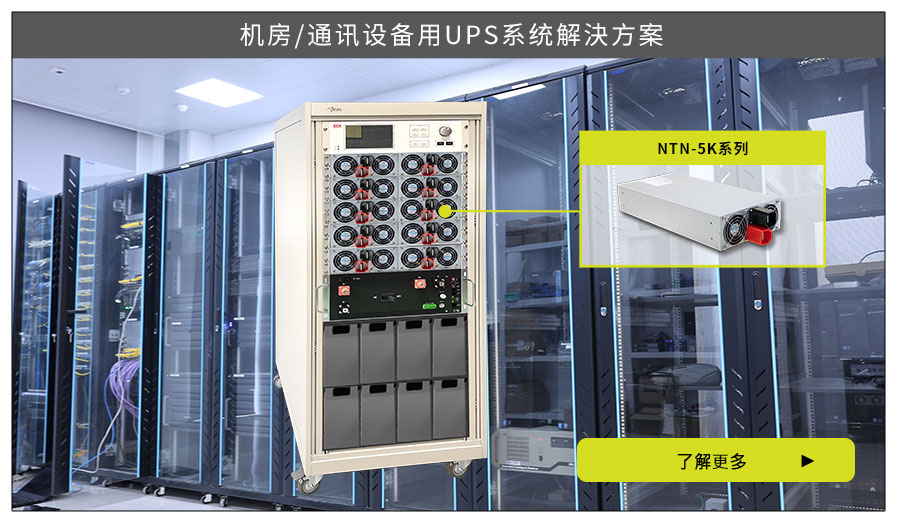

SHP-30K 系列为目前全球最高瓦数的单体 30KW 高功率 AC/DC 标准电源供应器,输入电压 AC 三相三线式,DC 输出则提供了包含符合低压 55V (<60V SELV) 及高压 (HVDC) 输出的 115V/ 230V/ 380V 等四种标准机型;特别适用于各类新能源与先进工业应用领域,如:储能柜、储能墙、氢能、风能与太阳能、EV 电动车 DC 快速充电系统等相关应用,工业 IT 大数据服务器与机房不断电 UPS 系统电源,5G 基地台及各类网通系统...

NCP-3200系列

3200W机架式二合一电源供应器与充电器

NCP-3200系列提供低压符合SELV的直流24VDC/ 48VDC与高压直流 380VDC等三种输出电压机型,可因应各类电力电子或通讯产业以及能源系统用户的设备使用。其中24VDC/ 48VDC低压输出机型,考虑能源供应系统应用场合需求,将直流电源供应器与充电器特别以韧体的设定做二合一的应用设计,适用于各类轻/重工业机械设备...

完整介绍

RST-7K5/15K系列

7.5KW / 15KW三相四线直流高压输出电源

为提供更多样式的标准电源来满足客户,明纬再推出全新设计AC输入三相四线式RST-7K5(7500W)及RST-15K(15,000W)标准电源,以2U低高度设计及高效率达95%,最大并联输出功率可达30kW。在输出电压应用提供115V、230V及380V三种机型,可提供不同产业应用,如工业设备、充电储能系统、电解设备、集中供电…等。此外,输出电压电流皆具备可程序化控制功能...

影音专区

SHP-30K系列—

30KW三相三线30KW高效率电源供应器

SHP-30K系列为交流三相输入转高压直流电源供应器,输出电压可分55VDC、115VDC、230VDC、380VDC,产品为2U高度设计,适合通讯、半导体、食品加工、工业自动化等设备应用。

系统电源—

电源管理与能源回收应用演示系统

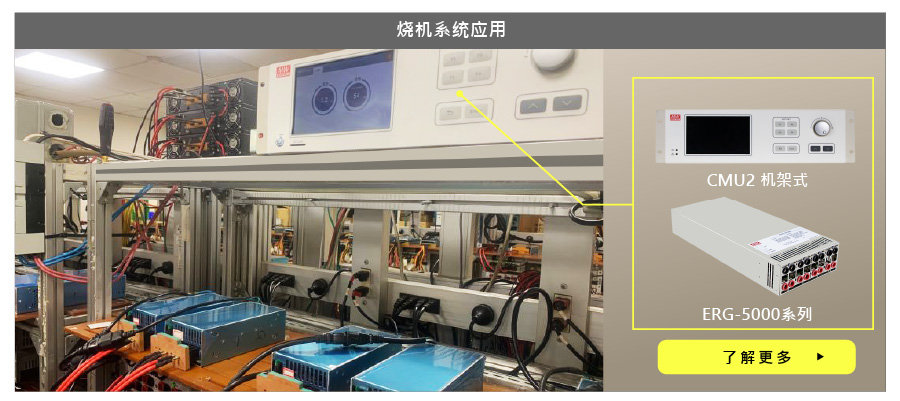

机柜式系统电源是由控制器CMU2C-R/CMU2A、电源供应器NCP-3200、能源回收电网逆变器ERG-5000与功率表组成,除了可以各别执行AC-DC电源管理应用与DC-AC能源回收应用,将系统DC侧共接时,可执行产品演示,可藉此执行PV功能演示、PC功能演示、无线通信功能演示与能源回收功能演示,进而让客户更了解这些产品的功能。CMU2C-R+NCP-3200可应用在直流集中供电系统上,如大瓦数雷射设备、恒流源系统与污水处理系统……等。CMU2A+ERG-5000可应用在电池化成/分容的放电过程,或者电源供应器或相关设备的老化烧机。

了解更多

ERG-5000系列— 能源回收烧机系统

ERG-5000(H)是一台可提供额定输入5kW及最大6kW的回收烧机系统,能源回收率最高可达到88%,能达到节能减碳的效果,同时有效节约电费成本。其烧机模式可选择CC或CV;4个通道设计可弹性的搭配待测物串/并联的应用,另外ERG-5000的烧机直流输入电压范围为10~60V,ERG-5000H为60~420V,适用于不同产品型号的烧机老化应用。内建CANBus通讯界面,可搭配CMU2A或者自行撰写程式来管控与设定。